Background

COAX Connectors’ Micro BNC 75-ohm insertion and extraction tool 96-1132 has been developed for use when connectors are closely mounted, and finger access is not possible. The tool locates on a slot on the back of the connector body for simple insertion and extraction. In the event of excessive force being applied to the Micro BNC Connector Jack COAX’s tool has been designed to break, saving the Micro BNC Connector Jack embedded within the more expensive equipment. COAX Connectors had experienced several reports of their Insert/Extractor Tool 96-1132 breaking in use, so the company was keen to address the reasons behind why this occurs.

Above: Insert/Extractor Tool 96-1132

Objective

To demonstrate the effect of using excessive force when inserting a Micro BNC Connector using Insertion/Extractor Tool 96-1132.

Methodology

Testing and computerised simulation involved the following COAX parts: Micro BNC Bulkhead Jack 67-461-1-D66, Micro BNC Plug 67-005-B66-FA and Insertion/Extractor Tool 96-1132.

Testing was carried out with increasing amounts of sheer force applied to the connectors with and without the Insertion/Extraction Tool. The objective of this was to establish the maximum force which could be applied to the connectors using the Tool without breakage of any of the parts occurring.

In addition to physical testing, using Solidworks an express simulation was run with static loads applied to the body of the Micro BNC. Simulations were run to shows where the forces are concentrated under various load conditions.

Results

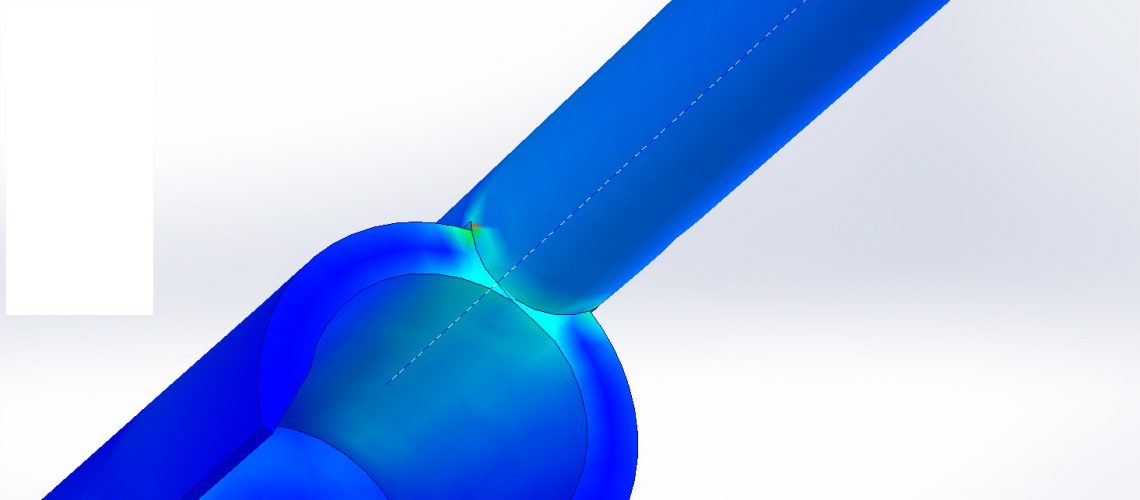

Increasing amounts of force of were applied to the Insertion/Extractor Tool (96-1132) and when the level of 0.8 Newton Metres was reached the tool broke. The computerised stress test images 1 and 2 below show in red shows the joint eventually ripping on the tool.

Image 1 – Solidworks stress test simulation highlighting where tooling would fail with excessive force.

Image 2 – Solidworks stress test simulation highlighting where tooling would fail with excessive force.

The body of the Micro BNC bulkhead jack 67-461-1-D66 had an increasing amount of force applied to it, to see where it would eventually fail, and this was at 1.0 Newton Metres of sheer force. See images 3 and 4 below. Image 3 shows where breakage would eventually occur and photo image 4 shows the damage that would be done to the connectors if the tool was made stronger than the connectors.

Image 3 – Stress test simulation highlighting where breakage would occur on Micro BNC bulkhead connector with excessive tooling force.

Image 4 – Photograph demonstrating connector breakage on lugs with more than 1.0 Newton Metres of sheer force applied.

Conclusion

It is essential that insertion/extractor tooling is manufactured to withstand less force than the connectors to avoid damage to the connectors installed within expensive equipment. In testing it has been proven that COAX’s Insertion/Extractor Tool (96-1132) will be sacrificed to save the connectors in this case Micro BNC bulkhead jack 67-461-1-D66 in the event of more than 0.8 Newton Metres sheer force being applied to it. This breakage at 0.8 Newton Metres of sheer force will mean that the 1.0 Newton Metres force limit of the connectors will not be reached, and the connectors will remain intact. All of COAX’s Insertion/Extractor Tools for use with Micro BNC Connectors are constructed in the same way to sacrifice the tool and not the connector in the event of excessive force being applied.

Issued: 19/10/23

COAX Connectors Ltd, 6-8 Colne Road, Twickenham, Middlesex, TW1 4JR, United Kingdom

T: +44(0)20 8538 9090 E: info@coax-connectors.com www.coax-connectors.com